|

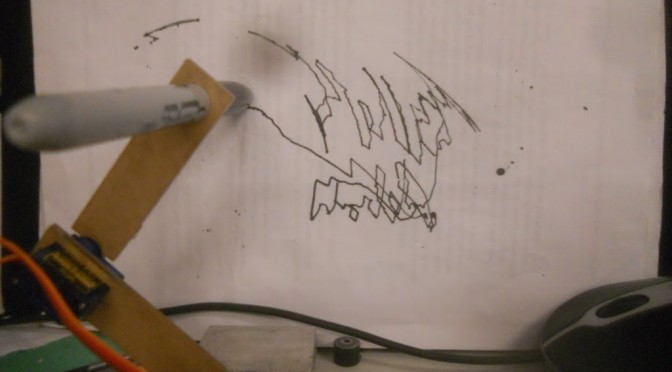

| values actually mapped correctly = some semblance of control. mapping painstakingly / experimentally determined |

|

| the setup |

actually very difficult to write words even with the arm controller (versus twiddling some potentiometers to control the arm), because the potentiometer to servo mapping isn’t precise and there’s a lot of slop (e.g. look at the dead space around the screwdriver)

time elapsed: probably 1 hr including trying to figure out how to draw things and documenting ^^ (~40 minutes to code this and map the values)

/**

* @file: RC control of servo

*

* @description

* theta1 = bottom joint pot value, theta2 = top joint pot value

* these were experimentally determined,

* I had one leg of pot connected to sig5v, the other to a voltage

* divider setup with a 1kohm=R2 and being read to A0 or A1 respectively

*/

#include <Servo.h>

Servo servo1;

Servo servo2;

int theta1;

int theta2;

int map1;

int map2;

void setup()

{

// pinMode(1, INPUT);

// pinMode(2, INPUT);

Serial.begin(9600);

servo1.attach(2,500,2400);

servo2.attach(3,500,2400);

}

void loop()

{

theta1 = analogRead(A1);

theta2 = analogRead(A0);

// map1 = map(theta1, 163,380, 0,130);

map1 = map(theta1, 163,360, 0,130);

// map2 = map(theta2, 1017,275, 0,160);

map2 = map(theta2, 1017,264, 3,150);

servo1.write(map1);

servo2.write(map2);

Serial.print(“theta1 “); Serial.print(theta1);

Serial.print(” map1 “); Serial.print(map1 );

Serial.print(” theta2 “); Serial.print(theta2);

Serial.print(” map2 “); Serial.print(map2);

Serial.println();

delay(20);

}