general pedagogy

https://stellar.mit.edu/S/course/ec/sp13/ec.717/courseMaterial/topics/topic6/readings/Penick_Where’stheScience/Penick_Where’stheScience.pdf (restricted to class) (ugh, I hate that I can’t share this article, it’s an excellent one. It’s from 1991, sheesh).

The basic idea is, this teacher started out doing a cool demonstration in class, however, when students went to do it themselves, they did the bare minimum needed to replicate it without much enthusiasm. Then, the teacher switched it up — he asked students to predict the outcome of the experiment, and also structured the demonstration such that the students themselves came up with some of the lab procedures, like adding water to acid very slowly, that the teacher would then try. The students then were very engaged and eager to figure out whether the experiment would work out like they thought.

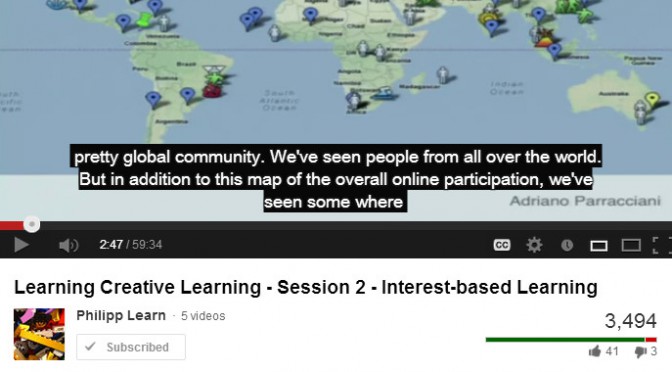

How global is online education?

|

| Wow, it really is really all around the world. This is exciting to me. They’re really at a scale where they can have pocket communities form on google hangouts. |

http://learn.media.mit.edu/syllabus.html The Media Lab Learning Creative Learning class, which actually has a tremendous following and is really cool.

(g+ community: https://plus.google.com/communities/106132864609383396284)

http://llk.media.mit.edu/courses/readings/gears-v1.pdf

Gears, serving as models, carried many otherwise abstract ideas into my head. I clearly remember two examples from school math. I saw multiplication tables as gears […] I am sure that such assimilations helped to endow mathematics, for me, with a positive affective tone that can be traced back to my infantile experiences with cars.[…] First, I remember that no one told me to learn about differential gears. Second, I remember that there was feeling, love, as well as understanding in my relationship with gears. […] the “body knowledge,” the sensorimotor schemata […] It is this double relationship–both abstract and sensory–that gives the gear the power to carry powerful mathematics into the mind.

Wah, cool,

http://www.amara.org/en/videos/Vnr37rOH9i24

Crowdsourced video captioning and translation! This is excellent. I will often spend a long time typing up video transcripts just for my own reference, so cool to be able to not just have it for myself, and also a really convenient interface online. Now someone should just hook this up to those language learning programs online… ALSO. Why can’t I type things and the software automatically figure out where in the video it belongs? I think that is definitely a do-able thing.

I am particularly interested in session 2 (interest-based learning) and session 5 (open learning).

session 5 notes:

“how and when learn should be under control of learners” (well, maybe not below a certain maturity level) and “who participates” not limited

“we want to crack it open, what we’re learning, figure out how it works at fundamental level” “things that let us dive in and not just sit back and consume are incredible important” “also produce” “still hasn’t changed schools in which most learning still happens” “there is a strong notion of activism” “[teaching at university] I want to go, everyone gets an A today, if you still want to come back, great lets learn something”

(all of this conversation seems focused on university level)

are MOOCs example of what have in mind, do they fall short in some way?

do need to interrogate what mean by open (not slapping on a label)

letting anyone sign up for a class is huge, don’t want to diminish that at all

but do want to ask, is open enrollment sufficiently open?

never took a programming course, learned from being exposed to people way better than me

(me: i wish that were possible in the open source hardware community to the extent it is in the open source software community! how can we make that happen?)

idea of debugging ideas, all sorts of things in open learning,

often best way to learn, push yourself to maybe things start to break,

toread: http://mako.cc/writing/unlearningstory/StoryOfUnlearing.html yay, pills. -.-

http://net.educause.edu/ir/library/pdf/ERM0811.pdf This reading is flaming awesome.

It is unlikely that sufficient resources will be available to build enough new campuses to meet the growing global demand for higher education

Open Educational Resources (OER) movement

Light discovered that one of the strongest determinants of students’ success in higher education— more important than the details of their instructors’ teaching styles—was their ability to form or participate in small study groups. Students who studied in groups, even only once a week, were more engaged in their studies, were better prepared for class, and learned significantly more than students who worked on their own.

In a traditional Cartesian educational system, students may spend years learning about a subject; only after amassing sufficient (explicit) knowledge are they expected to start acquiring the (tacit) knowledge or practice of how to be an active practitioner/professional in a field

“productive inquiry”—that is, the process of seeking the knowledge when it is needed in order to carry out a particular situated task

SXSWEDU

Online Learning

toread: http://www2.ed.gov/rschstat/eval/tech/evidence-based-practices/finalreport.pdf

“US Department of Education

Evaluation of Evidence-Based Practices in Online Learning

A Meta-Analysis and Review of Online Learning Studies”

I listened to two talks, which you can find if you go to the “audio” site and look up the titles. Some notes:

- Project Based Learning: The 8 Essential Elements http://schedule.sxswedu.com/events/event_EDUP14902

mostly “hey supply chains are actually difficult” and the actual implementation of a donorschoose but hyperlocal supply granting program instituted in El Paso, Texas

- MOOCs: Hype or Hope? http://schedule.sxswedu.com/events/event_EDUP16136

this is a big mess, e-commerce took 10 years: amazon is there, but what was in-between, cosmos delivered candy bars in the middle of night, …

this is the phase we’re in: people are going to try weird stuff, it’s not going to make any sense, but we’re trying, that transformation is happening.

change: not only matriculated students, now global. MOOCs are changing the concept of matriculation.

====

some talks i picked out to listen to in the future:

sadly does not appear to be online

Project Based Learning: The 8 Essential Elements

http://schedule.sxswedu.com/events/event_EDUP14902

The Double Bottom Line for Education Entrepreneur

http://schedule.sxswedu.com/events/event_EDUP14819

This panel will discuss social entrepreneurship in education and look at examples of education social ventures that have successfully scaled.

Tinker Tailor Solder Ply: Why Makers Rule in EDU

http://schedule.sxswedu.com/events/event_EDUP15386

Hear how makers are helping kids unlock their creativity while applying their STEM know-hows — and, in doing so, shaping how we rethink the value and purpose of an education.

==

Nation in Decline: Why We Suck At Science & Math

http://schedule.sxswedu.com/events/event_EDUP13045

Meet the Educational Stars of YouTube

http://schedule.sxswedu.com/events/event_EDUP15569

Breaking the Mold: New Models for Learning (K-20)

http://schedule.sxswedu.com/events/event_EDUP14826

The Magic of Making: Engaging Students As Makers

http://schedule.sxswedu.com/events/event_EDUP15925

We’ll look at the importance of creating makerspaces in schools, developing a community of practice around engaging kids as makers, and how online tools can enhance and extend the value of making to the broader community.

Think Outside the School: Learning is Everywhere

http://schedule.sxswedu.com/events/event_EDUP15382

How can we use social technology to foster peer-learning and to recognize knowledge acquisition regardless of where it takes place?

Based on the case studies of the Mozilla Open Badge project and E-180,

Digital Harbor Foundation

http://schedule.sxswedu.com/events/event_OEEDU0139

will share our experience designing a Common Core aligned tech and maker curriculum that helps place kids in real world paid internships.

Peer-to-Peer Marketplaces, Meet EdTech

http://schedule.sxswedu.com/events/event_EDUP7234

they also allow their educators to earn meaningful income by teaching online

Open Education: Still a Chasm to Cross

http://schedule.sxswedu.com/events/event_EDUP8716

The Problem Finders: Design Thinking Across School

http://schedule.sxswedu.com/events/event_EDUP13846

learn about new techniques for getting the best ideas, language use, and higher order thinking out of students.

Not Another Zombie Idea: Customizable, Open Digital Content Transforming Learning

http://schedule.sxswedu.com/events/event_EDUP990511

also the future of concept-based (bite-sized) learning leveraging multiple modalities (text, videos, exercises,interactive learning objects) that will help students and educators transform learning experiences.

====

EdX

Some thoughts on expectation management versus just getting courses up and out there:

http://electronicsdesigner.blogspot.com/2012/06/mit-6002x-circuits-and-electronics.html

“Given the prestigious name of the institution and their reputation for ground-breaking methods developed in the Media Lab, my expectation was that, as part of the transition to on-line delivery, they would have taken time to prepare a clear and thorough presentation of the subject, taking academic lectures to a whole new level.”

“I’m afraid the lectures have the feeling of “oh bugger, I forgot to prepare anything, I will do it as I go along”. You can get away with this in real lectures, but for video presentation then I’m afraid it isn’t good enough.” … “With all the resources of MIT, it must surely be possible for someone to digest these lectures and present them in the form of mostly pre-made slides

Developing Countries

One of the stories that was exciting to me about 6.002x was a university prof or student in another country who was like, hey, I will take this and make it an after-school program, because this topic isn’t really taught at my university (or something like that). I think MIT’s model of hands-on learning (mens et manus) is definitely gaining momentum (not MIT-driven, of course, but still). E.g. Skoltech, SUTD, and based on my own conversations with people such as +David Li, China’s government is interested in supporting makerspaces.

Is this actually true though?

Perhaps.

http://www.rovingbandit.com/2011/09/higher-education-in-developing.html

Are universities good candidates for foreign aid? Blattman thinks so;

Foreign aid’s educational blind spot http://chrisblattman.com/2011/09/03/7358/

Second, the aid community are on top of primary education like an overzealous mother. Tertiary education is pretty much ignored. The MDGs are both a cause and en effect of this sad state of affairs.

http://www.universityworldnews.com/article.php?story=20100918074103941

The United Nations is to focus more strongly on higher education in developing countries, Qian Tang, UNESCO’s newly-appointed Assistant Director-General for Education, said in Paris last week.