The Open Source Hardware summit 2015 is coming up. In preparation for that, I tried to make origami acrylic heels on the lasercutter.

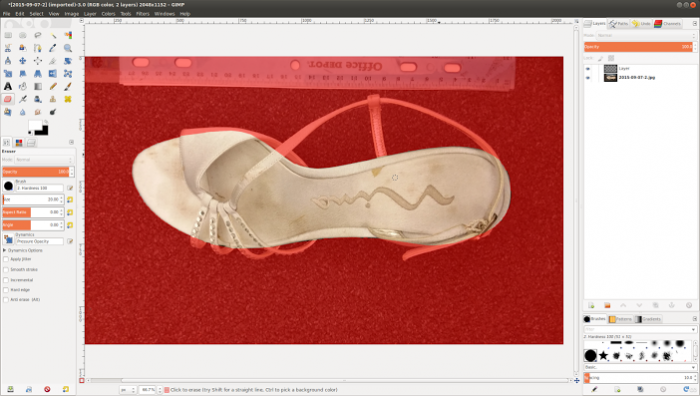

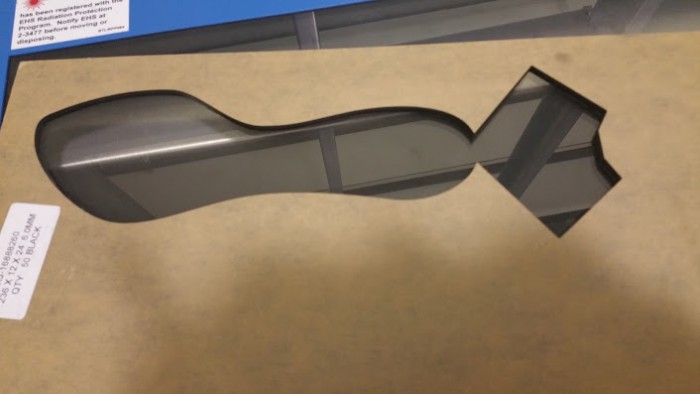

To start with, I traced an existing pair of heels that fit my feet (although I eventually want to modify the design, the straps are tough on my 4th toe).

I took a picture of the heel and then using inkscape “select continuous region by color” (shortkey: U) and the quick mask mode (to edit the selection more easily), (shortkey: shift-q I think) made a selection of the outline of the shoe. Then right click > Selection > To Path. In the paths toolbar tab, right click > export path and save as SVG.

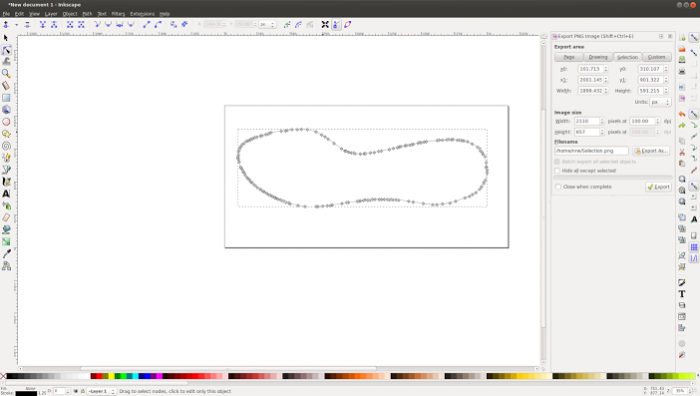

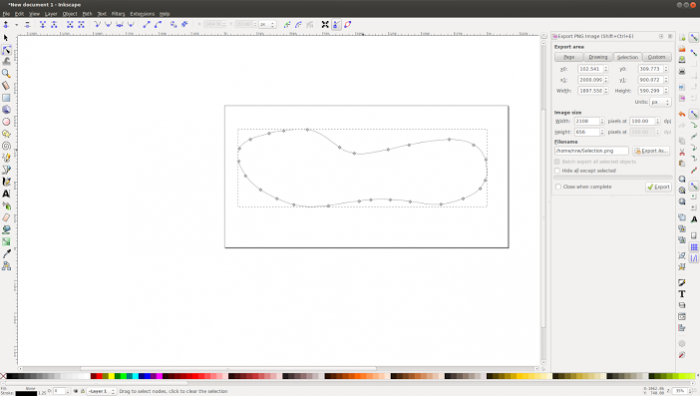

Open in inkscape.

Ctrl-L to simplify.

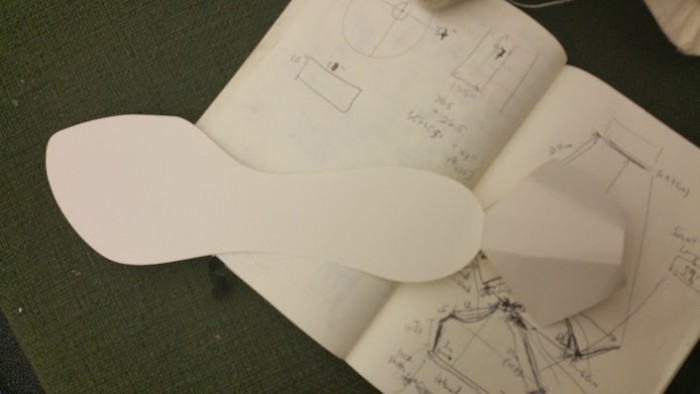

Now for the origami part. Credit for the idea goes to my friend M. We drew it out and prototyped it on paper first.

After scratching our heads a bit about the bending radius of the acrylic,which can get sharp 90 deg on the inner bend, we decided to go ahead and cut it out.

Now for the annoying manual bending step.I used a heat gun on hi for this, and would run it back and forth along the bend for about 40-50 seconds.

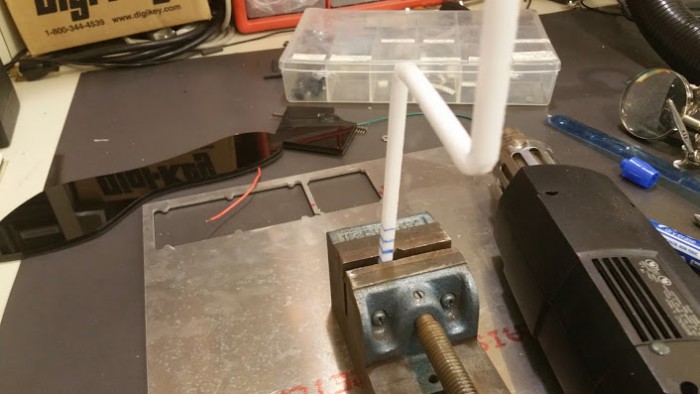

First I got some practic and some calibration in. Mark half-inches

then bend.

Now to try it on the heel. I thought I should bend one side first

but still ran into issues when it was time for the other two bends, since they interfered with any attempts to clamp them for heating.

Also, I may not have heated both sides of the acrylic enough, since the acrylic became bubbly when I bent it. . You also have to hold down the acrylic for a while while it cools, with something heat-resistant, or else it springs up a little. Here’s a picture of the issues with the second bend, which I couldn’t get as sharp

Also, I may not have heated both sides of the acrylic enough, since the acrylic became bubbly when I bent it. . You also have to hold down the acrylic for a while while it cools, with something heat-resistant, or else it springs up a little. Here’s a picture of the issues with the second bend, which I couldn’t get as sharp

On the final bend, the acrylic outright cracked.

At this point, I gave up. Here’s a picture of what it should look like, with me manually holding the pieces in place, and without testing by stepping on it and walking around in it.

I think I’ll be going with a 3d printed heel and have LEDs in it. I might return to this if I ever feel like duplicating the LaserOrigami setup.

I wrote the author of LaserOrigami for more documentation, who kindly replied

I only have the paper:

http://www.stefaniemueller.org//wp-content/themes/f8-lite/images/laserorigami/2013-chi-mueller-kruck-baudisch-laserorigami.pdfThe most important things are the following:

– you need to move the cutting table far away to defocus the laser (I set the z-value to 50mm or more to get a thick stripe where the material gets warm)

– the laser comes from above and thus heats the material from the top. to have it bend, the material needs to be warm from the top and bottom, so you need to run the laser a couple of times back and forth with low power so that the heat has time to sink through the material. only when the material is warm at the top and bottom it will bend.

—> if you have too much laser power, the material will be too hot at the top (you will see heat bubbles) and not yet warm at the bottom. reduce the power or increase the speed and try again.

– be aware that if you have a filter running, the air suction will cool the material a bit. so settings are different depending on how much you turn on the filter (best is to decide upfront how much you have the filter on and stick with it). the settings are also a bit different if you cut close to the air suction slit or further away.