Engineering Education

This post is a compilation of my thoughts as I begin working my way through the following post by Charles, which is 17k words long:

http://www.etotheipiplusone.net/?p=3035

My post is itself 7,700 words long and rather rambly and disorganized. You are forewarned!

This post is flat-out putting my research and thoughts down stream-of-consciousness style, complete with paragraphs of quotes from stuff I read. These quotes makes my style of writing unsuitable for any official media column, which wants the work of the Inpidual, but on my blog I view quotes as documentation and refuse to remove them. I tend to view summarizing them in my own words as needless duplicate work. In addition, this post is not very organized. I’ll revise this post some future date, but if I tried to make it actually organized I’d never post it.

In addition, in some sections a lot of MIT terminology (class numbers) is used.

0. Intro

I’m working on an engineering education startup and am thus working in this field for a living. As you might expect I have a lot of thoughts, theories, and opinions based on my own years at MIT and before (I did four years of FIRST Robotics in high school).

1. Why Read Background Literature on Engineering Education

I start by acknowledging the fact that I’m not an expert in education or engineering education and proceed by reading background literature on what people have done and thought about already over the decades. Thanks to the internet, in particular google scholar, this knowledge is merely a few mouse-clicks away. Academic research will always be limited in scope and not always directly applicable to my situation and what I’m attempting to do, but I would be remiss in not reading up on the situation when it’s so easy to do so.

From this background reading, I’m able to gain the terminology to begin conversing directly with people who have studied this subject and some understanding of social and historical factors influencing the current state of affairs that would come more and more into play as I attempt to scale any changes I seek to make in society. This reading also represents an attempt to understand which conclusions I have drawn from my own life apply to other people (wherein I am part of a trend) and which conclusions I have drawn from experiences in which I am the outlier (most other people react differently or have different experiences in their life). I believe this is another step crucial in improving and iterating on engineering education at scale. This belief, that it’s impossible for me to determine in isolation which of my experiences commonly apply to others and which do not by myself without being subject to clear sampling bias, reinforces my decision to do some background reading.

Although I acknowledge the sampling bias inherent in only polling my friends, who fall in the same social / cultural strata I do, the ease of doing so and my own curiosity means that if you’re my friend you’ll have been polled by me on various topics. “In your experience, has it been true that…” I believe that this is still better than simply relying on my own experiences, and I hope the previous paragraph explains how I attempt to continuously improve my understanding of the world. (in order to better take it over, of course, mwahaha)

With all that said, I also think it’s really fantastically important to act and not just study or observe all the time, even if you think yourself a unskilled or there’s the chance that your effort is duplicate work or that “experts” might react negatively to what you’re attempting to do.

With that, let’s begin.

Charles talks about:

“I have seen it happen over and over again. A Certain Scientific Department becoming uneasy with how ‘theoretical’ it has become, and with news of other universities’ more ‘hands-on’ approach to engineering making a comeback, tries to add a lab or design component to a class that in recent history has been entirely on paper. The students have never been exposed to real parts and processes before; maybe a few of them have, from their own personal experience in years past. The groups form, there’s much struggle and frustration at how stuff just doesn’t work as well in real life as they do in Solidworks or Matlab, and in the end, maybe one or two projects “work” and everyone else leaves with a really dim view of project classes in general, and some start resenting the Department for ‘not teaching them anything useful’. Does this sound familiar to you?”

Here, I’d like to give some historical context and terminology for this push-and-pull that Charles describes and is familiar to any historian or anyone who has read about the history of math curricula in the United States.

(http://www.csun.edu/~vcmth00m/AHistory.html)

“Broadly speaking, the education wars of the past century are best understood as a protracted struggle between content and pedagogy. At first glance, such a dichotomy seems unthinkable. There should no more be conflict between content and pedagogy than between one’s right foot and left foot. They should work in tandem toward the same end, and avoid tripping each other. Content is the answer to the question of what to teach, while pedagogy answers the question of how to teach.

The trouble comes with the first step. Do we lead with the right foot or the left? If content decisions come first, then the choices of pedagogy may be limited. A choice of concentrated content precludes too much student centered, discovery learning, because that particular pedagogy requires more time than stiff content requirements would allow. “

2. Historical Background of Engineering Education

Let’s talk more specifically about the history of engineering education at the college level. Chronologically,

http://www.nap.edu/openbook.php?record_id=11338&page=115 or in pdf format

http://www.nap.edu/catalog.php?record_id=11338 (requires free account)

“Yet, it is worth taking a moment to remember that until the end of the nineteenth century, the primary means by which a young man became an engineer was through a hands-on apprenticeship in a machine shop, at a drawing board, behind a transit, or on a construction site. […] it was not until after the Civil War, when the Morrill Act led to the establishment of land-grant schools, that the dominant pattern of engineering education shifted from shop floors to classrooms.”

(Patterns in the History of Engineering Education Reform: A Brief Essay. From the book Educating the Engineer of 2020: Adapting Engineering Education to the New Century ( 2005 ). This essay details the social historical patterns that led to this shift a century ago and is a fascinating read. Among other things, in engineering and engineering education, we see time and time again the influence that government grants can have. Also, it’s funny to read about how an inferiority complex influenced engineers as a whole back in the day to shift away from shop classes and gives me a smile as I consider how my own inferiority complex has pressured me to try to learn more theory).

http://digitalcommons.olin.edu/cgi/viewcontent.cgi?article=1021&context=mech_eng_pub

“Historically, engineering curricula have been based largely on an “engineering science” model over the last five decades, in which engineering is taught only after a solid basis in science and mathematics. […] The infusion of first-year design courses—later dubbed corner-stone (design) courses in the 1990s—was motivated by an awareness of the curricular disconnect with first-year students who often did not see any engineering faculty for most of their first two years of study.”

(Engineering Design Thinking, Teaching, and Learning. Jan 2005, Journal of Engineering Education).

http://mchua.fedorapeople.org/tmp/juntolin/1995%20Seely.pdf

“In effect, current reforms are responding to changes made in American engineering colleges in the years immediately after World War II (1939-1945), when engineering curricula first fully embraced an analytical mode of engineering science.”

(The Other Re-engineering of Engineering Education, 1900–1965. Jul 1999, Journal of Engineering Education).

According to Charles,

“My whole thesis, if it had to be boiled and distilled and refined down, is this: Give students the tools of practicality and channel their creativity first, and supplement them with the knowledge of theory and science later.

With our newfound historical perspective, Charles’s sentiment can be seen as part of a broader reactionary trend starting in the 1990s shifting toward design thinking and away from the analytical sciences.

3. My Thesis: Different Strokes for Different Folks

Given this historical context, my own thesis is “different strokes for different folks” or “different resonant frequencies for different students.” I find a hands-on approach more beneficial to myself, but acknowledge that there exist students (and professors) who do not like “applied” engineering at all and thrive with theoretical approaches. In this case, the parameter of engineering education we care about (tailoring) may be viewed along a spectrum from (a) continuously customized to each inpidual student’s learning strengths to (b) mass-fed to all students in the same way. By solely emphasizing either the theoretical or hands-on approach, we will neglect a subset of students. Furthermore, this whole emphasis on “theoretical” or “hands-on” is very obviously a simplified approach and not necessarily the best simplification either.

To be more explicit, consider this approach taken to an extreme. A model of learning that uses a binary pide between “analytical” and “applied” students can be used to chunk students into two categories. From the relative size of the two groups, we may target the larger group and write the smaller group off as a loss.

Analytical and applied may not even be the best binary pide of students, and more to the point is a binary pide the best we can do?

Let’s consider the background literature on this topic.

4. Existing Research on My Thesis

http://www4.ncsu.edu/unity/lockers/users/f/felder/public/Papers/LS-1988.pdf

“To overcome these problems, professors should strive for a balance of instructional methods (as opposed to trying to teach each student exclusively according to his or her preferences.) If the balance is achieved, all students will be taught partly in a manner they prefer, which leads to an increased comfort level and willingness to learn, and partly in a less preferred manner, which provides practice and feedback in ways of thinking and solving problems which they may not initially be comfortable with but which they will have to use to be fully effective professionals.”

(Learning and Teaching Styles in Engineering Education. Originally 1988; updated preface 2002. The author’s website, http://www4.ncsu.edu/unity/lockers/users/f/felder/public/, is also a treasure trove of “Resources in Science and Engineering Education” that I will need to peruse at a later date).

Hmm. So here we see that researchers have been considering this “learning-styles approach” for three decades already and that after extensive thought on the subject on engineer has, on the tailorization spectrum mentioned in part 3, picked somewhere in the middle! To be expected, yet surprising for me, since with “online learning” and computerized instruction picking up public fervor there’s been so much hype lately about how “teaching continuously customized for each inpidual” would be the best type of teaching possible. Yep, my own opinions are influenced by the culture I reside in.

A. Tangent about the Engineering Education Research Community

Turns out within this community there is a growing split between theoreticians and practitioners! Holy hexapods this is meta beyond what I expected. Incepptiionnn…

http://www4.ncsu.edu/unity/lockers/users/f/felder/public/Papers/PracticeResearch.pdf

“While the rigorous research movement has made valuable contributions to engineering education, it has also given rise to a concern. The engineering education research community has begun to split into two pergent and sometimes antagonistic groups: the theoreticians, who seek to understand the learning process at a fundamental level, and the practitioners, who continue to focus their research on improving teaching structures and methods. Those descriptions represent extremes, with many researchers occupying intermediate positions, but the existence of the two different camps and the danger of a widening schism between them are real.”

(Educational Practice And Educational Research In Engineering: Partners, Antagonists, Or Ships Passing In The Night? J. Engr. Education, 2013)

Uhm yea I am not going further down this rabbit hole right now. *exits paper*

5. Learning Styles Models: Criticisms

http://www4.ncsu.edu/unity/lockers/users/f/felder/public/Learning_Styles.html

“Principles and applications of four learning style models (Felder-Silverman, Kolb, and models based on the Myers-Briggs Type Indicator and the Herrmann Brain Dominance Instrument). The paper concludes that the choice of a model is almost irrelevant: teaching designed to address all dimensions on any of the models is likely to be effective, and all of the models lead to more or less the same instructional approach.”

“Matters of Style.” ASEE Prism, (December 1996).

Ah! This is a fascinating conclusion.

Below, I addresses my own lingering skepticisms about “learning-styles” models. This skepticism arose from when I learned that the popular “right-brain left-brain” and “visual/kinesthetic/auditory” learning-styles is considered by most modern education researchers to be a pile of horse dung. See:

http://en.wikipedia.org/wiki/Learning_styles#Criticism

“Many educational psychologists believe that there is little evidence for the efficacy of most learning style models, and furthermore, that the models often rest on dubious theoretical grounds.[34] According to Stahl,[35] there has been an “utter failure to find that assessing children’s learning styles and matching to instructional methods has any effect on their learning.””

Let’s dig deeper than wikipedia.

http://linksprogram.gmu.edu/tutorcorner/NCLC495Readings/Stahl_DifferentStrokes.pdf

Oh noes! It’s actually titled the same as my thesis, haha. “Different Strokes for Different Folks? A Critique of Learning Styles.” (American Educator, Fall 1999). And it does indeed have the quote cited in wikipedia and copied above and concludes

“Thoughtful educators have tried to make this work, and perhaps it is workable, but trying to meet all of the preferences of a group of children would seem to take energy that would be better spent on other things. This is especially true since no one has proven it works.”

Let’s go back from Stahl to Felder.

http://www4.ncsu.edu/unity/lockers/users/f/felder/public/Papers/LS_Validity%28On-Course%29.pdf

“Every two years or so, some academic psychologists conduct a literature review and conclude that no research supports the use of learning styles in teaching, and journal reviewer s and editors treat this conclusion as a new revelation that once and for all debunks learning styles. These pronouncements have never had the slightest effect on the world academic community’s extensive and continually growing use of learning styles models and assessment instrument s, but that has never deterred others from repeating the exercise two years later […]

Most learning styles debunkers base their arguments on the meshing hypothesis. They claim they have found no credible evidence that matching teaching to students’ learning style preferences leads to improved learning, so there is no reason to take learning styles into account when designing instruction. […]

Learning styles […] are neither infallible guides to student behavior nor made-up constructs that have no basis in reality, but simply useful descriptions of common behavior patterns. Although their validity is routinely challenged in the psychology literature, the most common learning styles models have been used frequently and successfully to help teachers design effective instruction; help students better understand their own learning processes; and help both teachers and students realize that not everyone is like them and the differences are often worth celebrating.”

(Are Learning Styles Invalid? (Hint: No!) On-Course Newsletter, September 27, 2010.)

Interesting. This is a more nuanced view than I have previously encountered and the one I will leave with at this point.

6. Return to Reading Charles’s Post, Part 1

Ah. I quote a lot when writing my posts (documentation!), but I’m at 2.5k words already and only just got to Part 1 of Charles’s post? Oh dear.

Hmm, interesting history about MITERS. Todo: write my own personal history of building things (analog to part 1) and MITERS (analog to part 2).

“where do you learn about how to design with and around the hardware or to use the tools available to you?”

This. This crucial skill is what we will be trying to teach in the second part of the NarwhalEdu Drawing, Robots, and Engineering course and what I spent a long time trying to explain to hackaday commenters.

Part 3 on Charles’s Post. Interesting history of the electric vehicle / go-kart section in 2.007.

Part 4.

One comment I’d like to make with regards to scope in design classes — from talking to a professor at the Tufts Center for Engineering Outreach, a crucial feature we’ll be incorporating into our own “build things contest” is a common theme. Turns out that if you leave the field wide-open people get lost and it’s less possible for students to learn from one another.

Part 6.

“for the most part I kept the selection hidden in an Instructors’ Only closet, but if someone “ordered” a part that was in the stock, it was available after 1 or 2 days of artificial delay to keep things fair; I had a queuing area for shipments as they come in, and the parts would magically appear in them.”

Huh! I… did not know that while I was TAing the class (the artificial delay).

“and shows again why this class might not be scalable unless you had multiple EV hacker gurus.”

Heh. I’ll give my own thoughts as a TA of the SUTD-gokart class with zero EV experience soon. (well, I guess hexarideablepod was electric, but it was definitely not a go-kart). EDIT: Didn’t make it into this blog post. Maybe next time.

Chicane? There’s a word for that funny turn? Haha.

In my view, what I had to contribute lay more along fabrication (”what’s a tap”) and debugging expertise (”halp this isn’t working” “okay let’s go download the manual online and read through it”). As in any class, there tend to be common questions that I was learning along with or just hours before. In fact, I’d say that by the end of the class everyone single student was 100% more proficient with designing and building electric vehicles than I was, since I’ve yet to build a working one (again not counting hexarideablepod). I approach explaining the design process differently than Charles does, and I think in part this is because of the “expert” paradox where it becomes impossible to remember just how overwhelming everything seems when you are starting out.

B. Tangent: Expert Teachers vs. Experienced Teachers

In other words, it’s possible to spend a long time teaching without become as good at it as you can be.

“Expertise is a process rather than a state. Experts continuously extend the outer edge of their competence.”

http://www.teachingenglish.org.uk/blogs/jenny-johnson/experienced-teachers-or-expert-teachers

Part 7.

“Many engineering students would prefer not to ask questions and tough/puzzle it out, when it is far more productive to grab a hint and move on, and you should be on the lookout for people who are too stuck trying to optimize in the wrong direction.”

Hmm, would have been good to know this was the philosophy Charles followed while working as a TA. Whoops! 😀

Part 8.

“I’ve received feedback a few times that the class was really’ you teaching yourself’, both expressing that positively and negatively.”

This is where I struggled as a TA to try to figure out where my building style fit into the class. My style, as a relatively inexperienced builder, is still more copy-paste “I Saw it On the Internet” than Charles’s. Thus, he would answer questions like “How do I make my steering linkage?” with “I don’t know the answer, you figure it out!” whereas I would answer by saying, “I don’t know, but you know, look at all these blogs your previous classmates wrote” while feeling vaguely guilty of not being a more technically-oriented instructor.

Let’s explain my experience with

I have the very opposite problem with strangers — I worried about bothering people so much that part of the reason my Fitbit supervisor refused to write a letter of recommendation for me for grad school applications was that I didn’t ask for help when I got stuck, instead struggling to solve questions on my own that were harder to solve because there’s a lot less MSP430 documentation than Atmega328 documentation online, which I was used to. So I was penalized pretty heavily for attempting to be too self-sufficient. I also discovered I’m not really a fan of writing firmware, but that’s another story.

I do like the point about how building a large go-kart reduces the fudge factor acceptable with smaller projects (on the scale of NarwhalEdu projects which can fit in your hand, and which I think are more appropriate for the freshman level of college).

Part 10.

“2.00gokart is not an attempt to start some sort of design revolution, nor is it meant to overturn the foundations of a modern engineering education. It is simply one other path, out of myriads, that motivated and spirited people have built in the interest of advancing the quality and accessibility of education for everyone.”

Well-said.

7. Overall Response

Alright, now that I have finished reading the post, I’d like to provide my response without reading through the ten or so engineering education papers I have queued up. I’ll maybe write another blog post tomorrow.

Charles starts out very strongly with his thesis that hands-on is the best thing since hobbyking and then sort of mellows out toward the end (“there are many paths”). In general, I found this post extremely useful as a snapshot of engineering education and the conclusions and theories about engineering education of one of my fellow MIT/MITERS engineers, as well as a catalyst for my own continued forays into the field of engineering education.

I am fortunately able to write a much shorter post as I have yet to have the experience in engineering / engineering education that Charles has had. I will note that due to my own sensibilities I have spent more brainpower on issues such as gender rather than solely on the value of hands-on education as opposed to theoretical classes. Perhaps I need to write my own post on gender and engineering education in order to catalyze my research paper reading into the area, but I’ll leave that for a future post. For a bit of reading into this subject, see http://miters.mit.edu/blog/2012/11/02/what-is-a-miters-2/.

Thus, I will split my response into the following portions, in analog to Charles’s post.

ONE. Pre-MIT

TWO. MIT

THREE. MIT – MITERS

FOUR. MIT – 2.007

FIVE. Post-MIT

8. Detailed Response

ONE. Pre-MIT

My high school had FIRST robotics, which I did for four years and which ultimately convinced me that I wanted to be an engineer. I didn’t really understand what mechanical engineering meant, other than building robots. I didn’t decide I wanted to go to MIT until I visited in 10th grade.

|

| hanna and I! we don’t seem to have changed much. |

Yet despite participating in robotics for four years, I found it easy to get sucked into doing the non-technical work, a tension always within me: technical work made me compare myself to others and feel bad, but I was really conscious of the gender gap all the time and wanted to learn the technical side.

In fact after four years my bucket list was like so:

“1. Learn to chain

2. Learn to run wire, specifially learn about the & hone my soldering skills

3. Drive the robot for at least ten minutes

4. Go on the field

5. Make a decision”

Really? After four years I still didn’t know how to break and reassemble chain? It’s like a five-minute thing to learn how to do, and I spent far more time being too agonizingly shy to ask how to do it than it would have to just learn it. (Nowadays I would just look it up on youtube). I often wonder if in larger teams (our team had around 50 students) the pision of labor is gender-split such that it’s very easy, if you go with the flow and are female, to spend four years and a crapton of time being inspired but not gaining technical expertise. In contrast to Charles’s experiences in FIRST robotics, in four years I never learned to CAD or uploaded a Labview program I wrote to the robot or to wire 24V drivetrains. My dad would always laugh at me: “All you’ve learned is to turn screws.”

Why So Slow places a lot of emphasis on the idea that very very tiny advantages and disadvantages accumulate over time, and presents a ton (actually; it’s taken me a month to work through this book it’s that dry) of research supporting this theory. My hypothesis (has not been investigated) is that guys who put in as much time into FIRST as I did got far more out of it in technical expertise. If true, is that my personality fault or partly attributable to gender? Another thing that Why So Slow taught me is that gender differences start being measurable very early, within months after birth. So I’m willing to bet that by high school these vague impressions I got had some basis in reality. Let’s not even get into how my parents didn’t exactly encourage me to go to the extra team meetings on programming and such during the summer that were invariably held at a guy teammate’s house.

This is why I will never ever be happy for long playing second fiddle to a guy around my age — we can work on different projects, but if we work on the same project it better darn well be one in which we are equals. Sorry Charles, writing this post has actually clarified that I am not happy simply being the TA to your class and would prefer to spend my time elsewhere. Thank you for the awesome opportunity though.

It’s so true that the gender of a person shouldn’t affect whether I am willing to take advice and learn from them. Why is it then, that if Charles were a gal I’d be happy to learn from someone who has years more experience building things than I do, whereas since Charles is a guy I just feel like I’m constantly being reminded of the possibility of systematic pressures that kept me from gaining this experience at a commensurate rate? Not sure, too busy being bitter to care, hah.

Of course, I recognize that I’m pretty darn fortunate compared to my MIT friends from rural areas to have gone to a public high school in Georgia with a FIRST team and a ton of AP classes, and it’s pointless to wonder about how else my life would have gone. My life is pretty awesome and blessed right now.

Another thing that I had was northern team envy, I felt like there was a gap in available mentors and facilities between the north and south. Don’t know if that’s true or not either.

But I’d say most of my feelings toward robotics could be themed around: inadequacy, inferiority, incompetency. My analysis of the situation at the time was as follows:

“Who cares what the rookies think, the honest truth is that I don’t know any of this stuff. I’ll be in a completely different place next year, now is the chance to learn this stuff and embarrass myself and no one will know next year. This is logical. So why is it still so difficult to be confident and speak forth my opinions; why am I still so afraid that people will find them ridiculous, or completely missing the point.”

Anyway, I had some small science fair projects of my own at the time, which is how I first heard of Instructables (did you know that back in the day they advertised show-and-tells at MITERS?) and built a version of the pringles can vertical-axis wind turbine. I also learned of ladyada around this time when I made a solar-powered USB charger (I couldn’t keep series and parallel circuits straight, haha) and learned to solder courtesy of my dad. Even then I was exploiting the school system to build things -^-^-

|

| inspired by http://www.ladyada.net/make/mintyboost/ |

TWO. MIT

Alright, high school’s over, I spend a summer at the CDC doing bio work and then head to MIT.

Hahaha heck if I know how to make a narrative or heads or tails out of my academics at MIT. I’ve actually been thinking about this a lot, how my attitude affects how I portray my path through MIT and there’s no clear “truth.” I tend to default by saying that I never got academics at MIT and was rejected from grad school and decided to go work on a startup. Consider this with how Charles portrays his path through MIT:

“That, combined with my attitude towards engineering as something fun and hilarious (instead of SRS BIDNESS) meant that I spent most of my undergrad career not paying attention to classes. I openly admit to and am proud to point out cherrypicking only what I found relevant to some project I had going on at the time and shutting out the rest”

My portrayal is objectively a very self-deprecating way of putting things. Who does this portrayal even benefit? This sort of modesty certainly hasn’t stopped internet haters from hating on me.

- I could point out that I never took 6.003 and 2.004 or finished 6.302 and only limped through 2.737 by relying on Shane. Or I could say that I was so awesome that without ever formally taking a controls class I dared to take a grad mechatronics class and passed it.

- I could say that I was rejected from grad school, or I could say that I only applied to one program (MIT) with a very clear idea of what I wanted to do. If they weren’t going to support my working on that, then I would go off and work on the idea anyway by co-founding my own startup, and I darn well successfully did exactly that (see: kickstarter).

- I could say that I limped my way through MIT, or I could say that despite dealing with being hospitalized and paranoid and depressed and other crap I graduated in mechanical engineering from MIT in four years while being less stressed out than many people I know.

- I could say that I’ve never had a really successful UROP or internship, or I could say that after trying out the possibilities, I went back to my childhood dream of being an entrepreneur, became one, and for now have found where I’m happy.

- I could say that our kickstarter hasn’t gone viral like Heidi and Bayley and Daniel’s oneTesla, that I’ve never made a really pro-looking project. Or I could say that I had firm educational ideas and goals in mind (make a kit that makes people think “I could build that!” and is designed to be taken apart so people go on to build their own thing) despite strong cultural and economic incentives to not do so (everyone thinks Apple is the pinnacle of design and that quadcopters and 3d printers are the coolest ever). *

* As our goal is also to be able to impact a wide audience, the benefits of using something that’s hyped may outweigh the benefits of a more principled kit design that only reaches a smaller audience. We’ll probably try both and see.

Anyway, getting ahead of ourselves here. Back to MIT. In general, my feelings at MIT didn’t change terribly much from my feelings about robotics in high school: I felt incompetent, inferior, and inadequate. For the most part, MIT didn’t give me grand theories about how the existing academic system didn’t fit me and others like me.

Charles:

The classes I did the worst in were the ones that I couldn’t connect to anything I was building. The drudgery.

I felt instead judged and found wanting at MIT. I didn’t fare well grade-wise even in project-based classes such as 6.131, 2.007, or 2.008 that my friends loved. All these classes did was make me compare myself to my peers at MITERS and feel sad.

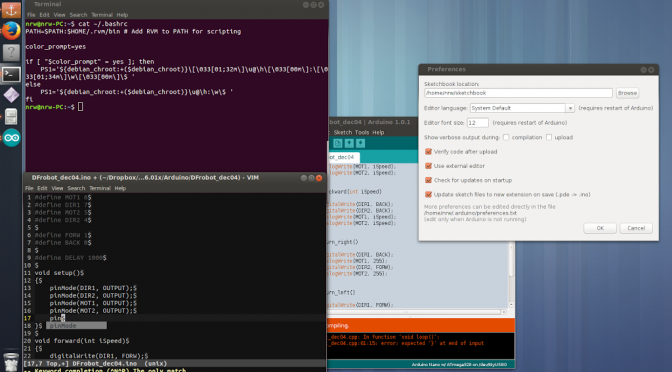

Glossary: 6.131 Power Electronics, a very time-consuming and awesome lab class. Mostly EECS/MechE sophomores and juniors. 2.007 Design and Manufacturing I, sophomore MechE class (build a robot). 2.008, Design and Manufacturing II, junior MechE class (build a yoyo). MAS.863 How to Make Almost Anything, all majors/years.

|

| MIT / hell ambigram |

|

| my 2.007 bot. read more here |

6.131 in particular was a class I thought I would love, but instead destroyed my confidence so utterly that even after graduating sometimes the thought of opening Practical Electronics for Inventors, which should be a fun read, filled me with dread.

|

| 2 AM 6.131 parties… |

|

| uguu traumatic final project: 48 hour 24v h-bridge, never finished |

Perhaps the class I like the best was MAS.863, How to Make Almost Anything, but for me it felt like the only classes I did well in were “soft” classes instead of science classes (and therefore I was inadequate, incompetent, inferior). I’m not sure if I pick this class ranking up from society or from my long-time impression that anything I was good at must have been easy. That class is awesome — learn a new tool every week and do a project with it. There was no fear of “where is the Morally Bad Copying line” — you were encouraged to learn from each other and document the frick out of everything and learn however you could (be resourceful). Your projects were encouraged to be entirely your own creation, so there was “design” and not just “machining” in it. As Charles points out, though, sometimes there’s a lot to be learned even in “copying” something. My one project that was an iteration of an existing design — a shelving unit made out of a single 8×4 piece of wood, which I rejiggered to cut out on the CNC shopbot — still taught me useful things about Solidworks. (Mostly I really wanted a usable shelf).

|

| shelf -> solidworks. read more here |

THREE. MIT – MITERS

I became heavily involved with MITERS, MIT’s student-run hackerspace, founded in the 70s before hackerspaces were even a thing. I first heard of MITERS in relation to dumpster ping even before visiting for CPW, but that’s for another story. At CPW I got a bunch of LEDs from MITERS really awkwardly, and my next forays into MITERS weren’t really until second-semester sophomore year. I started taking over secretarial duties and building hexapods at MITERS and then next thing I knew I was president.

I summarized my goals as president in a previous post: http://miters.mit.edu/blog/2012/11/02/what-is-a-miters-2/

A year later, I wouldn’t say my efforts were really successful in terms of getting the administration to know about us in a positive light or to encourage more persity in MITERS by getting rid of the “we’re an intimidating elitist bunch of hackers and you are not welcome. N00b.” impression some people got. I can’t even say that my efforts brought new members to MITERS. That’s okay, that’s part of experimentation.

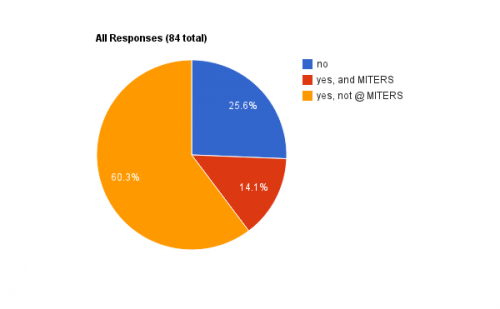

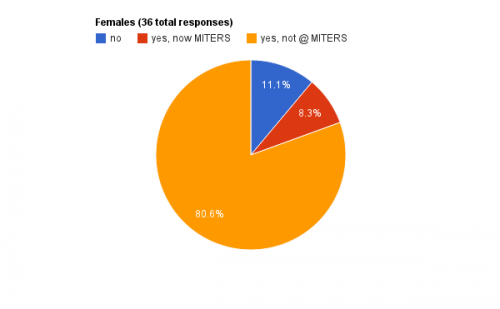

Were you ever intimidated by MITERS?

“whoa these people are so awesome, it’s so awkward when I ask n00b questions, etc.”

- yes, but now I hang out at MITERS

- yes, that’s why i don’t hang out at MITERS

- no

But this was perhaps my first forays into engineering education. After taking MAS.863 How to Make Almost Anything I realized I’d learned a lot and could help people with different things. That was the inspiration for the seminar series “build all the things”. The idea is that if we gave people a starting point, they’d have a reason to come hang out around MITERS. The first seminar, a 555 seminar, had over 100 people queued up to take it.

|

| EAGLE seminar |

One unfortunate consequence of BAtT being super-popular at first (or at least more popular than the 5 extra people MITERS can support) was that it was held upstairs in a clean environment and very few people ventured into MITERS afterward. But all in all BAtT surprised me in how many people were willing to show up on a Friday night for something they didn’t get credit for just because they wanted to learn to build things. 555 LEDs are thoroughly documented online and the components readily available at MITERS, yet people found utility in a bit more hand-holding than before.

I think one good thing about MIT is that it has taught me that people come in with very different backgrounds and no one will judge you for not knowing things. Just ask. I’ve met people who ask questions I would never dream of asking before consulting the internet, yet the atmosphere at MITERS has been really great. Being very definitely not a top student academically in college as opposed to the situation in high school helps too.

In a future post I’ll touch on how my mood heavily impacts how much I’m able to benefit from an environment like MITERS.

At MITERS I built things. Lots of things. Crazy things. Terrible crazy things.

| read more here |

I loved staying up until dawn with MITERS folks talking about really terrible crazy awesome technical things. I hated not understanding what people were talking about. But I sure as heck started out copying things and Designing by Looking at the Internet.

|

| look familiar? I copied my leg design straight from http://pacess.blogspot.com/2010/08/amigo-hexapod-leg-design-03.html |

Actually, I felt really crappy about this for a long time. My hackaday mention was for a project I implemented off of a really detailed instructables. But you know what? Whatever. I did the wiring myself, figured out how to add a sweet adjustable racing chair I crufted from some basement, figured out how to mount the motors in a removable fashion (well, not actually). I learned things.

| Work in progress |

(I’m still sad I lost the camera that had my pictures for my entire summer’s worth of working on hexarideablepod on it).

So that’s my experience with MITERS. The main conclusion re: engineering education: a lot of people can benefit for a tiny bit more guidance, like a catalyst, rather than just being thrown into the waters of MITERS.

The way we used to do it was have people show up on build party nights and show them the giant stores of stuff we had accumulated and a few projects that people had built and then say, “have at it!” We noticed that in those cases people tended to come in for a few minutes, leave, and never return. So now we’re trying different things. I tried organized seminars that cast a wide net. The current president is trying semi-organized one-on-one mentoring.

Speaking of “here’s a ton of cruft,” I tend to also categorize builders into two categories, those that create awesomeness from stuff lying around, spending less money and more time, and those that tend to spend money to get the exact parts they want and execute according to a plan. People can definitely transition between these two states — I’ve veered sharply toward the latter as I’ve started to earn money, but I can see how you can learn things a lot more in-depth with the former approach, and I’ve always considered it the more “hardcore” or legitimate approach. You can see sharp contrasts from person to person as well. Apparently when going commercial it works the opposite way around though.

FOUR. MIT – 2.007

2.007 is Design and Manufacturing I, for sophomore mechanical engineers.

As mentioned before, I applied to grad school, most specifically to work on an EdX version of 2.007 (again, don’t apply the way I did — if you want grad school, tell them you want to do research). I had TA’d 2.007 as well, where I developed A Lot of Opinions on TA work.

(A) Give them a heads’ up on the material you’re about to cover. Most TA’s took the class a little while ago and will do great with a refresher.

(B) Give them a definite hierarchy if there’s more than five or so people.

(C) Some TA’s have never TA’d before! Best to let them talk to those that have TA’d extensively before.

(D) Communicate your expectations to your TA’s and how they can best help.

(E) Give them feedback, otherwise how they feel they’re doing may be entirely porced from how you feel they’re doing.

Anyway, things I learned from TA’ing the class: you don’t have to know everything and it’s fine to say you don’t. Just help them work through the problem, especially if they’re new to debugging, or point them to someone who likely has more knowledge on that particular subject than you do.

My observation was that the experience for 100+ students was overall a bit haphazard due to variations in what they got to do and a lacking in the above five components.

One issue that keeps cropping up is whether to compile a list of common mechanisms, their various implementations and failures over the years, and their pros/cons, and provide it to the students or not. Copying is Bad, or so all of academia would like you to think. But perhaps copying is okay with attribution. Why shouldn’t the students get a ramp in and the robots get more awesome every year? Why shouldn’t there be a communal database of attempted designs that gives immediate insight into the value of documentation and working with your peers? The structure of the class (variations on the same themes every year) would be great for this.

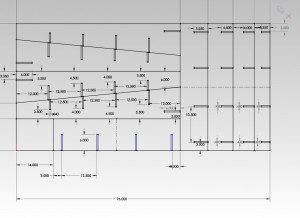

Something like this should definitely exist for drivetrains, at the very least, or perhaps they should be covered in actual 2.007.

I’ve actually wanted to have something like this for FIRST for a long time, because the veteran teams and teams that have a lot of returning mentors benefit tremendously from their knowledge of archimedes spirals, hoppers, ball eaters, and other common design motifs.

I agree with Charles on this point though — I’m not certain whether it would be better or worse for the MIT class overall. Because on the other hand, it’s hard to come up with creative or novel designs when you have in front of you designs that “work” and there’s a time pressure, so instead everyone would just iterate or poorly copy the existing designs without understanding why they work or missing important details.

I tend to believe that over time change toward constraints on information flow disappearing is inevitable, so we may as well facilitate it and control how this develops.

On a separate note, a lot of students would benefit from exposure to all the components available to them, which they often discovered too late to incorporate into their designs. Todo for some future TA or professor.

I’ve never had access to class evaluations so I guess I am missing that crucial bit of feedback.

In conclusion: Communication is key in working with TAs, it’s unclear whether more or less design documentation is better for student learning and enthusiasm in robot contests, and documentation of components is a must.

There’s this constant push-and-pull between iterating on the class as much as possible and having to update all the documentation, though. This is friction that technology should solve.

FIVE. Post-MIT

Right. So I applied to grad school (specifically, a Masters in MechE at MIT) and failed to get in. After taking a nap my reaction was actually one of great relief, and now I’m really happy where I’m at, so likely it’s all for the best. In my application, I didn’t try to model myself into a Model Grad Student and instead clearly expressed my desires, so not getting in is probably a good sign I would be happier elsewhere.

I can’t help but be bitter that life circumstances prevented me from double-majoring in 2 and 6 in exchange for the terrible grades and lack of grad school I got, but that’s okay. And it sort of sucks to be one of the mystery Statistical Women who didn’t continue on to graduate school, but whatever.* I’m happy and healthy and that’s… actually amazing.

*Or if I was being self-deprecating I could say “I am too dumb or lazy to get good grades.” Truth is impossible to discern. If I have the energy, may as well pick the most useful interpretation that provides me with solace or the willingness to keep trying (instead just rolling around in self-deprecation).

Instead, I set to work on an idea Josh first voiced after a talk by Sal Khan at MIT — combining online education with hands-on projects. How did I learn to build hexapod? The shop resources and my friends were definitely infinitely useful, but a lot of it came from random internet scrapings. So I definitely believe it’s possible to learn engineering online.

I also loved the idea of building things bringing together people from cultures all around the world. See: visiting makerspaces in China, the list of hackerspaces all around the world, the Chinese diy markets on taobao and letsmakerobots.cn.

|

||

| ballcopter in beijing, china. compare to: |

|

| charles’s diy ballcopter. cambridge, MA, USA |

Cross-cultural!

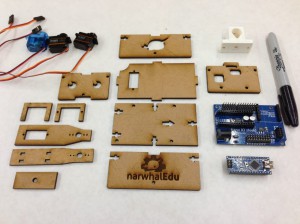

So that’s what I’m working on now with the awesome Hanna and Cappie: NarwhalEdu 101, Robots, Drawing, and Engineering: An Online Introduction to Engineering Course. Hanna and I are interested in female outreach and Cappie is interested in rural outreach, thanks to our respective backgrounds. W00t onwards to an awesome future!

7. NarwhalEdu

So after all these engineering education experiences, let’s talk about how I’m applying all of these themes and thoughts to NarwhalEdu.

First, some lessons we learned from actually running classes in person with K-12 students and talking to teachers and professors on engineering outreach:

(A) The hook needs to be in the very first class. We originally designed to start with blinking LEDs and ramp up to the drawing robot arm, but re-organized to have students build the robot arm in the first class.

(B) Having concrete chunks that can be accomplished in 30 minutes to an hour. In general, design like martial arts belt tests.

(C) Don’t spend lots of engineering effort when something easier will work just as fine. We were focused on drawing faces and spent a long time on this when having a “copycat” arm turned out to be just as fascinating to students.

(D) Requiring trigonometry will cut out a lot of high school students.

Our near-final curricula may be found here.

Additionally, something unique we are trying (since I really do want students from all around the world to talk to and learn from each other) is having the second part of the course be taking apart the kit and building their own robot with it as part of a contest. In educational circles this is called formative assessment, and I have high hopes for this.

In addition, in designing for classrooms a very different mindset is needed than when designing for the extracurricular inpidual learner as we did.

(A) Teachers are really really busy. Make it as easy for the teacher to adopt as possible.

(B) Kits need to be designed to be built and taken apart and put away very rapidly or else must be completable in 45 minutes or less.

(C) Kits need to be durable and low-cost and usable by multiple students at once so that schools can reuse them and amortize them over lots of students. And students are VERY good at destroying things.

(D) Alternatively another model is to design for a reasonable “class materials” cost, for instance around $50 a class. This naturally limits your reach to well-off students and school areas.

In contrast, our kit is designed to look so simple everyone, even “non-mathsci-people,” go “I could build that!” We also, as mentioned before, designed it such that people wouldn’t be satisfied with its base state (a risky move!) and would want to either improve it or take it apart and use its components to build something of their own.

The conclusion? I’ll let you know in around April when we finish running our course, or when I hear back from Stanford’s hapkits class or UT’s microcontrollers class.