hm, haven’t updated in a while.

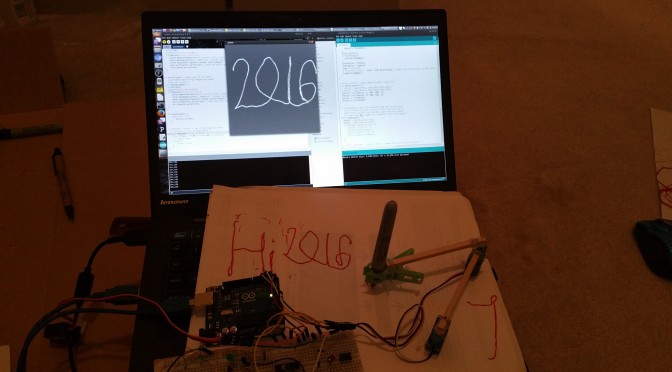

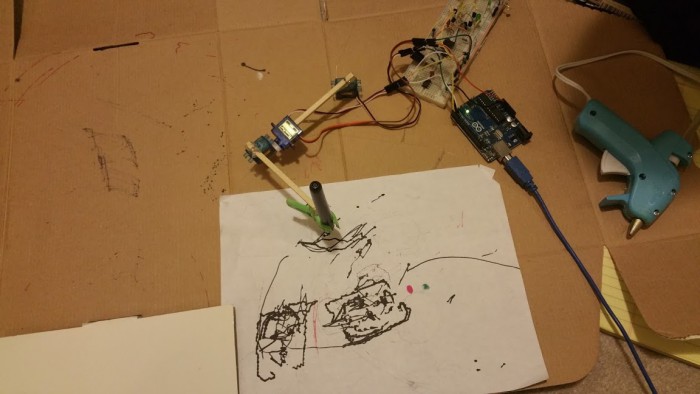

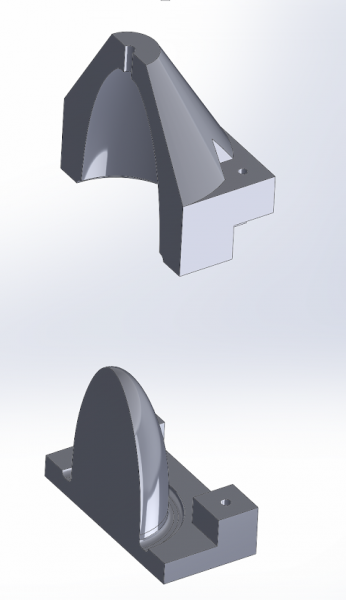

i built a lot of robots with parents over the winter break. i built a robot arm and refreshed on inverse kinematics; more specifically, make sure your servos are rotating as you expect: IK goes counterclockwise since angles increase that way, but your servos may increasing in a clockwise direction… a simple map(theta, 0, 180, 180, 0) will fix your problem if you catch it.

processing takes in x,y coordinates drawn on the screen and spits them out to arduino over serial, which does the inverse kinematics and spits out the theta values to the servo

https://github.com/NarwhalEdu/CopyCat/blob/master/Code/basicsIK/basicsIK.ino

or for the one where it draws what you draw on the screen, https://gist.github.com/nouyang/b312b9ea5c67baa0c914

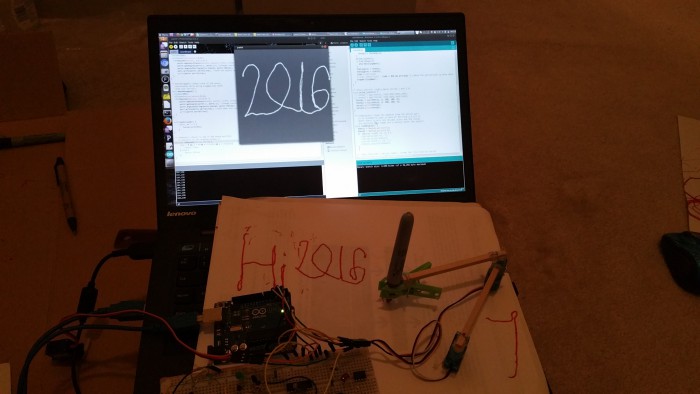

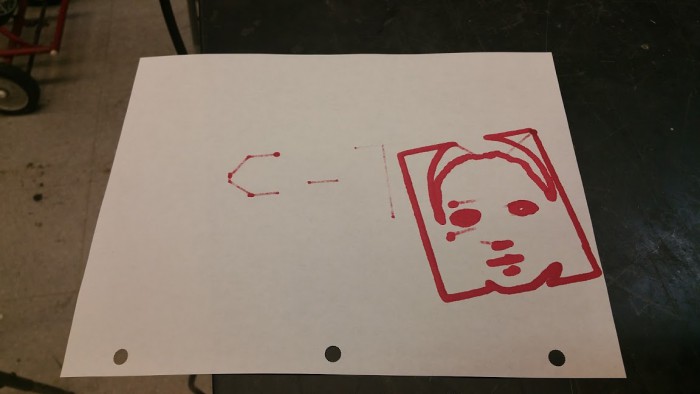

also tried to face.

it does not face well, in part i have derpy three year old code

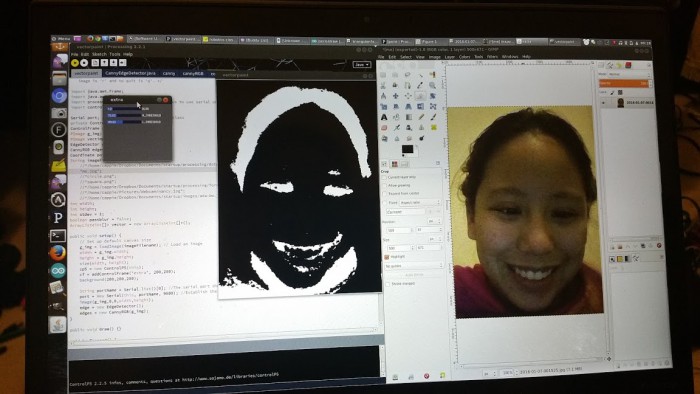

this processing code takes a lot of processing libraries. thresholds image, performs canny edge detection, then a walking algorithm (look at each black pixel by scanning image in x and y, see if neighbors are black as well, then walk along that pixel) to turn the edges into vectors. then output to robot, but robot is limited in resolution (arduino servo library) and cheap hobby servo overshoot.

below you can see preview in python. (basic code, I basically copied the output from processing into a text file and added some python code to that to plot the values)

is to check image is within the working envelope of the arm. IK is fixed with arm “up”.

problem of walking algorithm: adds a box around the image. irritating. need to rewrite code. looking into open cv.

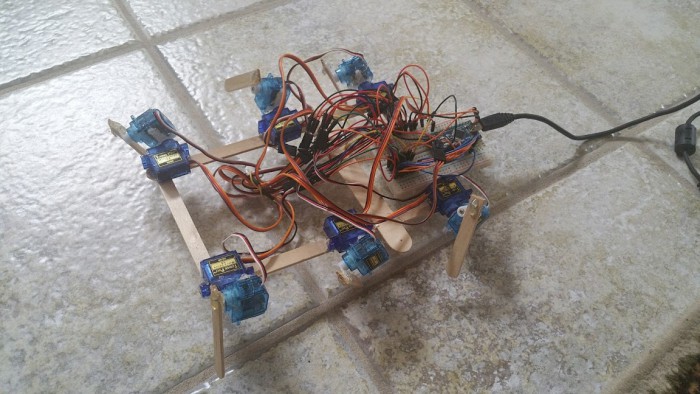

i also rehashed my hexapod project with 12 servos and popsicle sticks

basically this https://github.com/nouyang/18-servo-hexapod/blob/master/arduino_may13_2011.pde

but modified to work with the servo configuration on the rectangular robot, and added code to allow you to step through the gait with “j” and “k”: https://gist.github.com/nouyang/d9b6474e3ee412b9b05b

need to implement the other gaits; also, this moves so smoothly, envious, but they have lasercutter :3

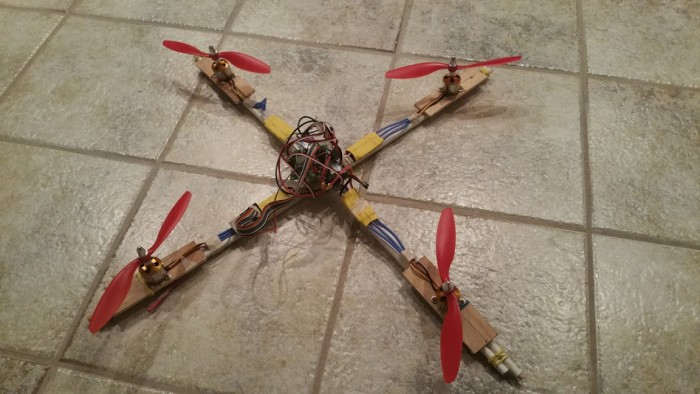

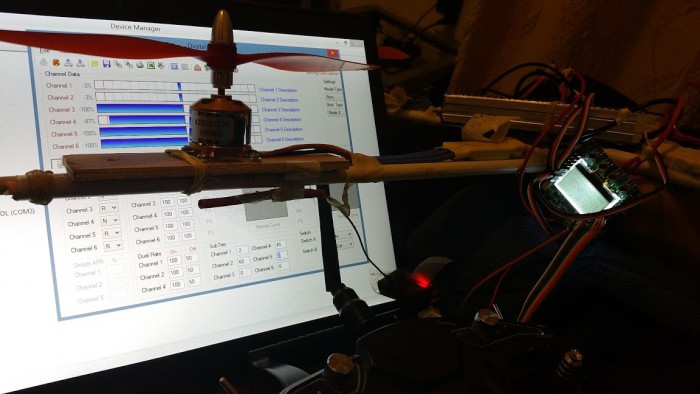

worked on quad, now stuck at calibration stage 😡 because i have not built quad before, i could not push through this in a day or two unlike the drawing arm and hexapod.

made from a sad clothes drying rack we took apart

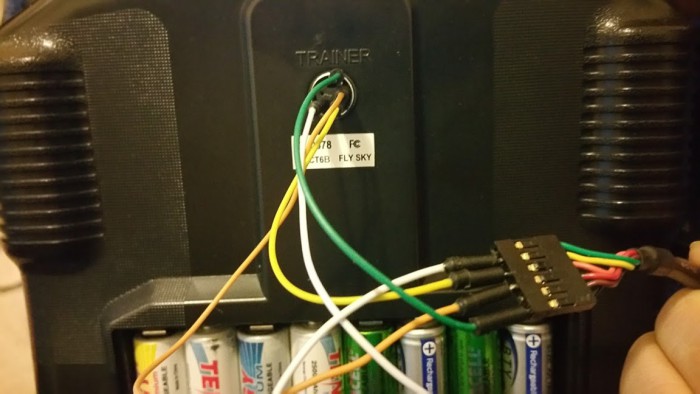

we couldn’t find the original cable for the transmitter, so we connected the ports up with a FTDI -> USB cable as per http://psychoul.com/electronics/how-to-make-your-own-usb-cable-for-hk-t6a-calibration

used http://www.sgr.info/usbradio/download.htm and calibrated my servos to zero… took a while to realize it *can* and *should* read the current values, guess my wires were loose, but the values because a lot easier to input. used the kk2 screen to fix some controls that were reversed from what the kk2 expected (left = left and not right, etc.). zeroed all the values on the kk2. turns out (minus the flipping controls) I could zero just as well on using the trim knobs on the controller itself.

went to visit NASA space museum in houston. they had little robot that made and served you froyo. adorable.

also, some regal looking hexapods in the actual NASA workplace.

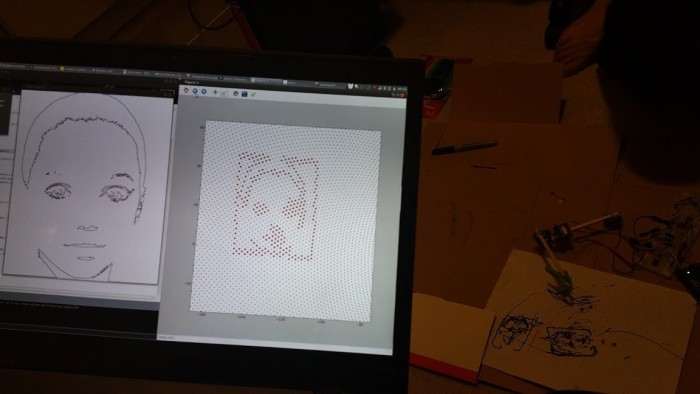

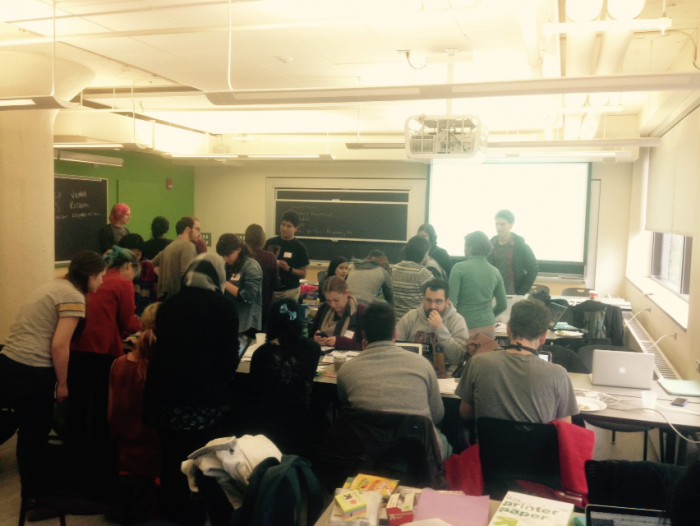

at MITERS I got a robot arm working with lots of help from MITERS / London Hackerspace / john from BUILDS. For robot arm competition. http://robotart.org/

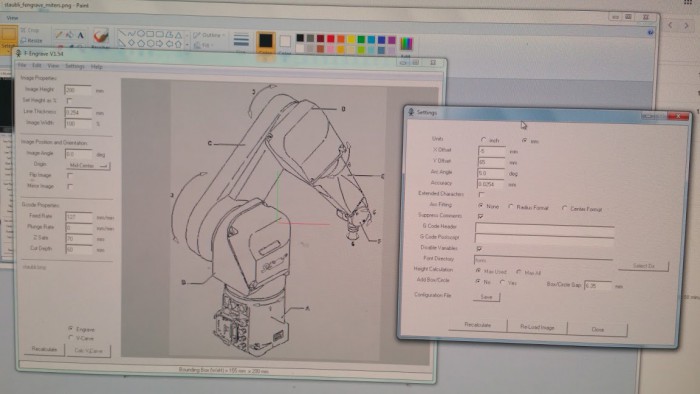

i’m now robot art-ing. here is using Fengrave on a black and white image with appropriate offsets to produce gcode (well, limited to G0 and G1 commands)

face code still derp. (streaks are because i wrote gcode translator, and it goes to x,y,z position instead of x,y and then z). too many x,y points. draws slowly.

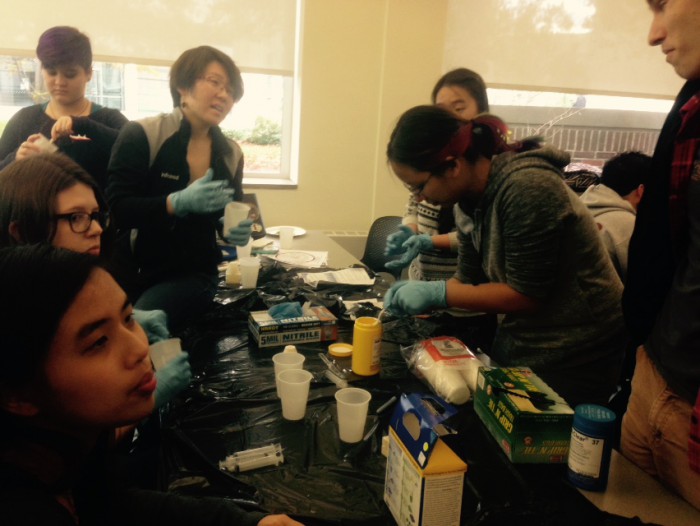

michael made crayon extruder (=metal tube + power resistor) and also pen mount. crayons = hard to control flow rate. started making square, then pooped out a lot of melted crayon. alas.

learned a lot of patience dealing with old manuals, 20 year old operating systems / controllers. main issue turned out to be a dumb calibration assumption (robot had arrows; should have ignored them and used indentations instead).

https://github.com/miters/gdmux gcode -> V+

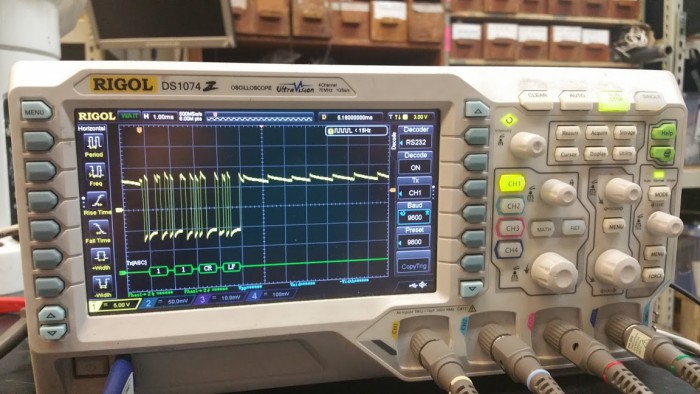

also, i learned about oscilloscope rs232 decoder! had to invert to get it working properly (zeros are high in rs232?). scope ground, tx line. bam, now you can check whether you are actually transmitting all the carriage return and line feeds you need…

currently: reading up on image processing. openCV. http://web.cs.ucdavis.edu/~ma/SIGGRAPH02/course23/notes/S02c23_3.pdf

terse update. more details available if questions exist.

many thanks to my parents for being excited and not jaded