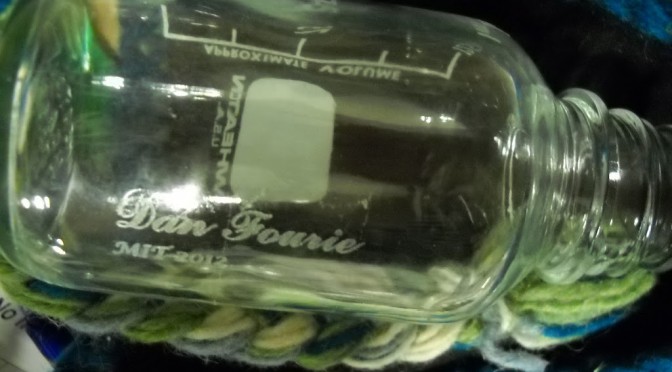

lasercutter: etching glass — went very quickly. I suspect the anodized aluminum setting may be overkill and can go much faster (perhaps they’re settings for straight up etching metal?).

What was this?

last minute crvftmas (everything you give must be “crufted” aka freely obtained, our hall’s version of secret santa) gift: laseretch lab glass bottles (clean autoclaved) I got off of reuse a while back

|

| I meant it when I said 50 lbs of lab glassware. 4 boxes. I only took about half from the reuse post too… |

|

| pre-etch |

Had issues due to irregular shape of bottle with placement and getting it straight :/ oh well (you can’t really tell from the photos)

|

| I ended up doing putzputz, winning MASLAB robot, (this year’s hall tshirt design, MASLAB team composed of 4 putzen including dfourie), on the back |

Also, thicker bottle could not use due to limit of how deep z wise the bed can move o.o

BTW lasercutter settings for 100kw epilog co2 with gas assist:

|

| 200 ppi, 40-60% power, 60 speed. |

and more pics on picasaweb as always.

https://picasaweb.google.com/113942194695013581888/LasercutterFun#

Spring making round one — I am still going to investigate manufacturers. but diy:

http://www.instructables.com/id/Make-your-own-springs-in-seconds/

Someone legitimized it in a comment:

“Many years ago I used to make springs this way on a lathe. We used commercially available untempered spring wire and after we finished we heated up the spring to red hot and dropped it into fish oil to temper it.Some times we would make special custom springs by soft annealing standard off the shelf springs and straightening them to salvage the wire. Then we would rewind them to suit the job at hand and re-temper.”

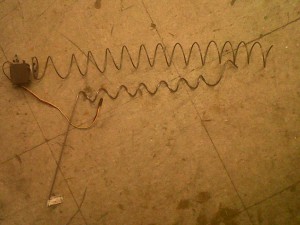

my Emergency!Labduein60minutes!results:

|

| comparison between real vending machine coil off of ebay and my hand-wound in 2 minutes one I compensated for non-spring steel (unlike Real Coil) by getting thicker diameter (plain steel) wire. |

Material acquisition trip to TAGS (right off of porter square T stop in cambridge, MA, next to shaws and radioshack)

|

| hi, receipt for techfair grant. also if you click for larger pic you can see what I bought |

|

| everything I could find at MITERS and that I bought, includes some thin spring steel. Also, ~2” OD pvc pipe I wanted to wrap my spring around |

Well, find out pvc pipe does not fit inside chuck (compare to hole) and is just too small to be gripped by OD jaws.

Learned about “flipping” jaws, or in this lathe’s case swapping out OD jaws for ID gripping jaws. Thanks shane colton and matthew hon

|

| step one, take jaws out by backing it out all the way with chuck key |

|

| they’re numbered 1-3 (or 4) and must be engaged by scroll (spiral thing that turns when you turn the chuck key) in that order to have an even grip |

Well I can’t find the right sized ones,

|

| they’re curved. top one’s threads are “inner diameter” gripping, but too small for the chuck currently on the lathe |

so I gave up and used the smaller diameter aluminum rod stock seen above.

|

| starting it was difficult. There was a preexisting throughhole in the (hollow) rod that I stuck the end of the rod through |

|

So, then I twisted it upward and pressed it to the rod with the glove. This was awkward to do. I immediately applied the square steel stock but you can see I had issues getting it pressed against the stock and creating a uniform spacing, since I only had one hand (spinning the lathe with the other). Surprisingly easy and fast.

|

| yea, very uneven result, will need to do more trials (there went $5 of weldable steel rod, ⅛’’). went very quickly, even by hand. |

|

| you can see starting out I didn’t get it to follow the rod closely like in the vid, though I am using thicker diam rod |

|

| end result again |

probably still need use light sensor detect when item vended, safer b/c of uneven nature of coils (can’t dead reckon with degrees of rotation)

==== todo: order light-up buttons, rfid reader, more servos (or hijack from hexadancingpod :/)

(tangentially, this is a ref for designing springs, linked off of make: http://home.earthlink.net/~bazillion/intro.html)

look how they do it automagically / industrially: http://home.earthlink.net/~bazillion/Trusprings/index.html and sexy video: http://www.youtube.com/watch?v=Ix4-UUelDc4