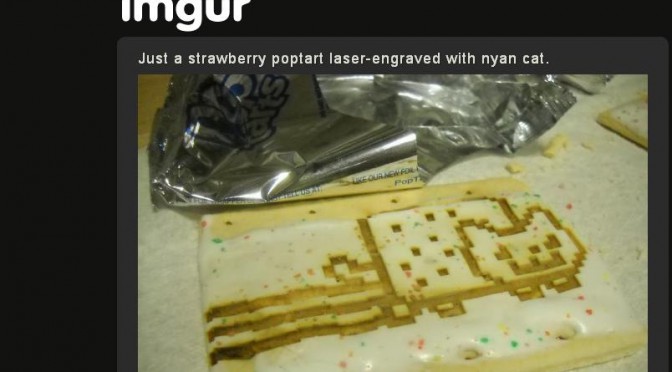

nyancake

Uhh I’ve been doing a lot of blogging and neglecting my other work, so here is minimalist style ftw.

|

| nyancake? nyangummi? |

My hall’s thanksgiving (putzgiving, alums come back for this) was two Saturdays ago. I tested out the nyancat cake mold:

|

| apply release agent, aka cooking spray / pam — otherwise doesn’t come out well. also, sprite+cakemix mixture should not be too gloopy. add flour if accidentally pour too much sprite. |

|

| many fail results. Here, did not let bake long enough. (much longer than box says — I baked a bit lower temp based on silicone mold research, ~325deg C, and for say 1 or 2 hours) |

|

| demolded too quickly, also did not cover in saran wrap to retain moisture afterward |

|

| nyancake party~! nyan nyan nyan |

|

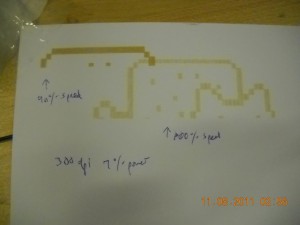

| probably the best of all my nyancakes. you can see that the minimum mold feature size — the sprinkles — were too small for the resolution of the cake mix and actually resulted in holes. |

|

| speed cooling jello in freezer. recipe used: the lego gummies from instructables |

Class-based makefile includes:

avr-objcopy -j .text -O ihex ./v0.1.45.out ./v0.1.45.c.hex

man avr-objcopy

-j sectionname

–only-section=sectionname

Copy only the named section from the input file to the output file.

This option may be given more than once. Note that using this

option inappropriately may make the output file unusable. >__> <__<

So the class makefiles should be fixed to include “-j .data”The internet says

“The makefile above DOES NOT create a proper HEX image and is a bad example. When creating an image, not only does the text section (which holds the code) need to be included but the data section (which holds any initialized data) also needs to be included.

The remedy for this is correct .hex rule to to copy the data setion as well

Example:

$(OBJCOPY) -j .text -j .data -O ihex $(PROJECT).out $(PROJECT).hex

” http://www.micahcarrick.com/avr-tutorial-digital-output.html

bmayton: that actually explains a lot of odd bugs that I’ve been seeing with peopleusing constant arrays, since the array data is never getting copied into the

program

So the actual model of what was causing my bug was, I believe, without calling another function the compiler goes ahead and uses the array to insert the correct commands into the compiled code. But when I used a subfunction, the compiler loads the subfunction which the microcontroller calls, but the ucontroller does not have the array data to look up what to set DDRB and PORTB to.

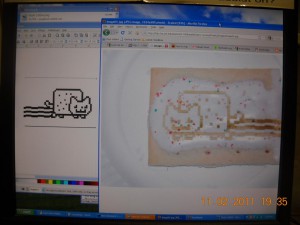

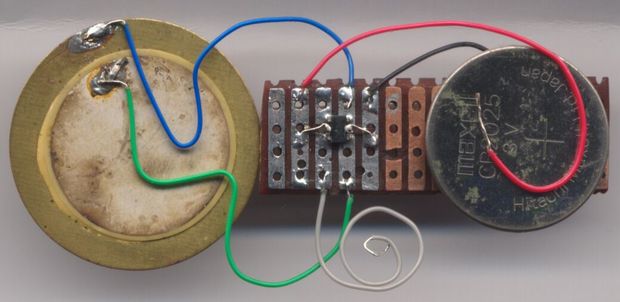

Anyway, then I proceeded to hack together terrible!code and get PoV working. I used oloepede’s sample image ‘cos I’m all about the laziest and quickest tests and ‘cos olopede is awesome.

|

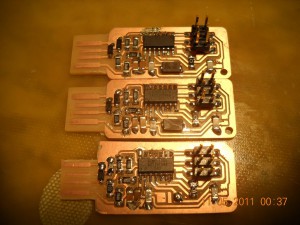

| eheh derp ripped off ISP traces / headers |

|

| works fine waving it by hand (without camera extended exposure time, hard to see entire “olopede” message — can see maybe three letters at a time. dead reckoning PoV timing — no sensors.) |

Doesn’t do so hot on the drill. Mess with timing? Although I spun it slow and fast (and in-use yoyo spins quite fast). May require sensors (fan pov as seen on dealextreme — product designer has better idea of speed of motor while yoyo has more variable speed. maybe they used hall effect sensors, ‘cos it was resilient to me slowing down the blades.) to get stable image.

See video:

https://picasaweb.google.com/113942194695013581888/PoVYoyoPersistenceOfVision#5681157457783660930

Vending machine

Right, essentially two weeks until final projects due. Aka time to start cramming on vending machine.

What do I have on hand? Arduino uno, extra servos leftover from when I bought out all the old 2.007 servos., zipties, handheld drill, a corkscrew. Found some rectangular metal thing to act as guiderails lying around MITERS scrap pile. Also found a block of wood lying around the floor.

Mod a servo to be

continuous rotation servo

(essentially turn it into a cheap RC motor that comes with motor speed controller in a convenient package for mounting) —

aka remove mechanical stop on gear

|

| apply flush cutters to stop on gear |

and remove pot, which like all pots doesn’t turn infinitely — make sure to be gentle ‘cos pot is held in by internal screw, why it doesn’t just fall out normally

|

| stick pot on outside, chew a hole for it in the casing — i abused flush cutters |

see How to Hack a Servo by Daniela Faas http://stellar.mit.edu/S/course/2/sp11/2.007/courseMaterial/topics/topic12/other/Servo_Hack_large/Servo_Hack_large.pdf)

springs / coils

Attach to corkscrew (from real vending machine) I bought off of ebay to see what real mass manufactured ones are like so I can make fake ones DIY like http://www.instructables.com/id/Make-your-own-springs-in-seconds/

Drill out servo horns (1/8” bit fits zipties I found) and attach to corkscrew with zipties

|

| it vends a block! haha. terrible setup is terrible. |

Video here:

https://picasaweb.google.com/113942194695013581888/VendingMachineOpenHardware#5681154916854562050

Yea, not a very interesting proof-of-concept (a “duh are you an idiot” one), but it was very satisfying to me.

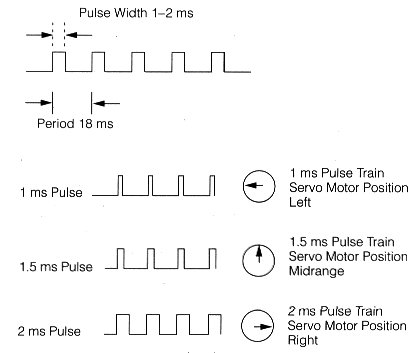

Oh right, I tried to use hot glue to hold the pot in one place, since that affects how the servo reacts to servo.write() (pot adjusts when it goes fwd/reverse) — I just used

myServo.write(50) with a 0.5 sec delay

myServo.write(90) with a 3 sec delay

myServo.write(130) with a 0.5 sec delay

to calibrate the pot so that servo was completely still at 90. And then attempted to hot glue. a bit flaky– not good enough for long-term banging around but good enough for dirty proto.

Not clear from pics, but to test it I’m holding the servo still with my hand.

![Nyancat cake mold, working PoV [not so yoyo], vending corkscrew test (mod servo for continuous rotation)](https://orangenarwhals.com/wp-content/uploads/2012/10/DSCN3324-672x372.jpg)