inspired by Designer Nori except theirs turned out a lot better (how did they get their seaweed to burn so white and not be affected by the humidity of the rice?)

|

| Designer Nori. img src [x] |

recently made some sushi for the excellent cathy wu

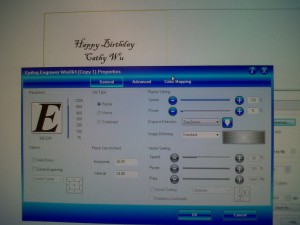

lasercutter settings epilog 120w: raster, 600dpi, 100% speed, 5% power

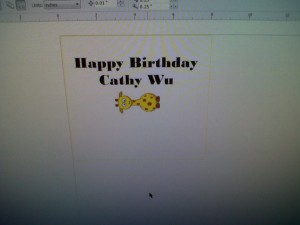

step 1. coreldraw + clipart I borrowed from the internet

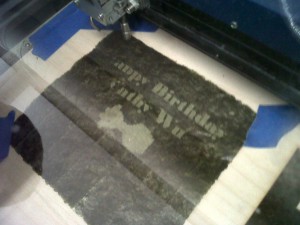

step 2. print to lasercutter using aforementioned settings

(without taping the seaweed down, it would go flying everywhere thanks to air assist constantly pulling air out of the lasercutter)

step 3. make all the ingredients for sushi

(rice with white wine vinegar seasoning, some raw bell pepper, a lightly boiled green onion strand, egg, and some carrots blanched for two minutes, where I learned blanche = immediately quench in cold water to stop cooking from continuing)

I didn’t try any so +Cathy Wu will just have to let me know how it tastes.

|

| words facing up just for show! obviously no one will read something on the inside of the sushi roll… |

step 4. roll it up

rice goes on 2/3 of the roll. make sure to spread the rice in the right place (just think about it carefully) and that the words are facing down unlike the previous picture which is just for show or else the words will be covered up.

Seems to fair worse when the humidity of the rice affects the seaweed.

|

| i’m wearing a chaihuo tshirt — it’s a makerspace in shenzhen, china |

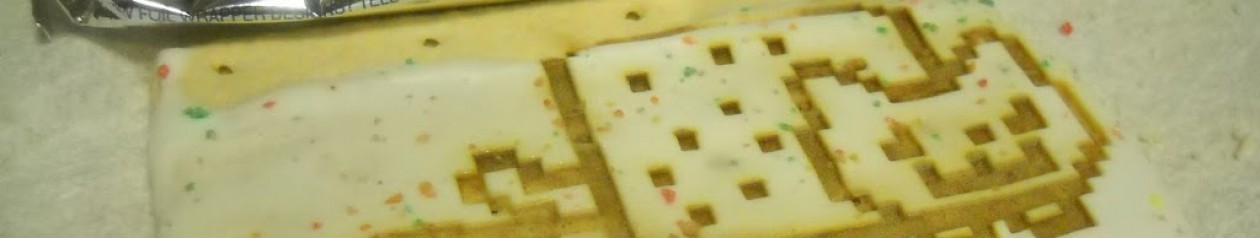

Nyansushi?

Obligatory nyancat related laser thing.